Dual Fluid LFTR’s are easy to reprocess

Dual Fluid LFTR’s are easy to Reprocess

The nuclear materials of a properly-designed, two-fluid (LFTR) Liquid Fluoride Thorium Reactor are extremely easy to process. This is because the fuel (one-fluid) and the fertile blanket (the other fluid) are already liquids. This immediately eliminates the first step in typical solid-fuel reprocessing, which is converting the fuel to a liquid.

This process is well-described in a document prepared by ORNL (Oak Ridge National Laboratory) scientists and engineers in 1967: Fuel and Blanket Processing Development for Molten-Salt Breeder Reactors (ORNL-TM-1852, PDF, 4.1M).

“One of the most attractive features of a two-region, [liquid-fluoride] reactor is the ease with which the fuel and fertile streams can be processed for removal of fission products and recovery of bred material. The fluid streams are easily removed from and returned to the reactor without disturbing operations, and the processing methods are relatively simple and straightforward. On-site processing is a primary requirement of a [thorium] reactor, which would be at an extreme disadvantage if a sizable inventory of fissile material were held up in decay cooling and transit.

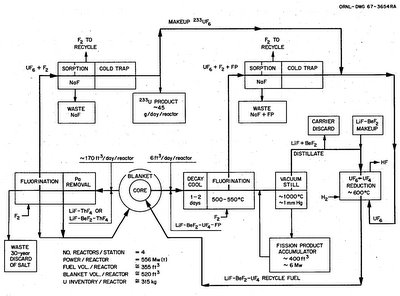

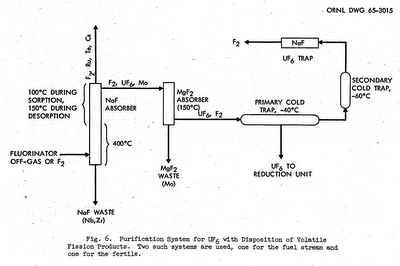

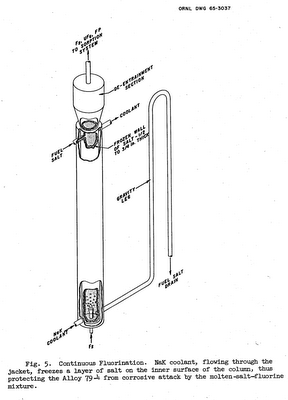

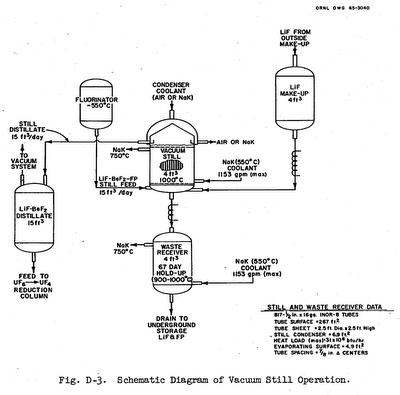

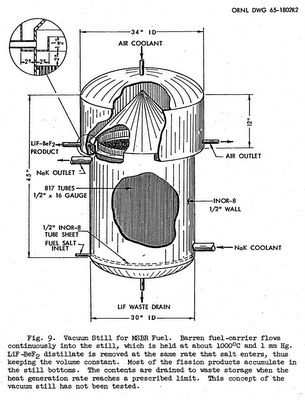

“Four major operations are needed to sufficiently decontaminate the fuel stream of an [LFTR]. These are fluorination, sorption of UF6, vacuum distillation, and salt reconstitution. The fertile stream requires fluorination, sorption of UF6, and for maximum effectiveness includes protactinium removal. These operations represent the most straightforward processing for achieving a high-performance [liquid-fluoride thorium reactor]. The technology for fluorination and sorption is well-developed (through the operation of the fluoride volatility pilot plant at ORNL); the other operations have been demonstrated in small engineering experiments and/or in the laboratory. The process for each stream is capable of economically recovering more than 99.9% of the uranium, 94% or more of the LiF-BeF2 in the fuel carrier, and more than 99% of the LiF in the fertile stream.”

[quote align=”center” color=”#999999″]Two simple processes, fluorination and distillation, are capable of processing the fluids of a two-fluid liquid-fluoride reactor. Fluorination is a very simple process and does not require the fuel salt to be cooled for any length of time before treatment. In fact, fluorination of uranium is done extensively in enrichment facilities.[/quote]

[quote align=”center” color=”#999999″]Distillation is also unique in that it actually reduces the volume of treated fuel, unlike conventional solid-fuel reprocessing which inflates the volume of the fuel tremendously through dissolution.[/quote]

When I first was studying nuclear energy, it didn’t take me long to realize that what was really needed was a breakthrough in reprocessing so that thorium fuel could be used. What I didn’t realize at the time was that solid nuclear fuel would never be as easy to reprocess as liquid-fluoride fuel. I truly believe that the liquid-fluoride reactor is the reactor that makes the thorium option not only viable, but compelling.